Olive Oil

The Author: Diego L. García-González and Ramón Aparicio, Instituto de la Grasa (CSIC), Avda Padre Garcia Tejero 4, 41012 Seville, Spain

Introduction

The first olive oil producer was primitive man who employed a stone mortar to squeeze fallen olives and noticed that oil was released (ca. 5000 BC). Ancient civilizations of the Middle East and the littoral territories of the Mediterranean basin have left clear evidence of flourishing olive cultivation and oil production.

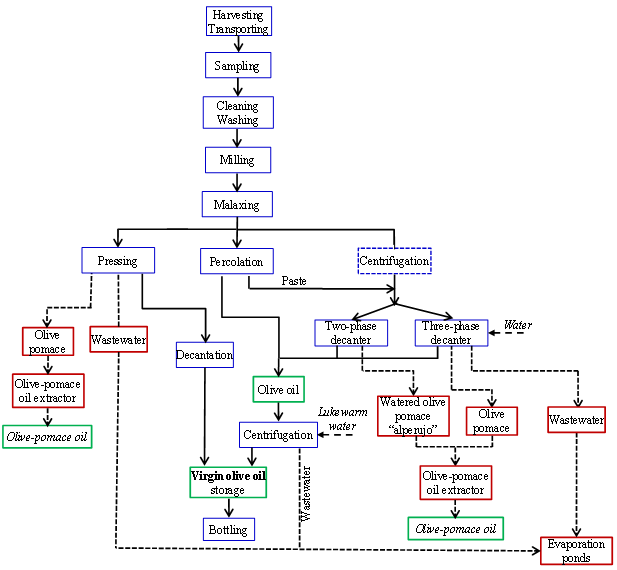

The improvement of olive oil processing has been influenced by technological evolution over the centuries. The Greeks designed the first screw presses but it was the Romans who contributed to the technological developments in olive processing by expediting the crushing operation with the millstone crusher, the trapetum, and improving the separation system with the introduction of presses. The increase in trade within the empire also contributed to major progress in olive processing. Since then, the pressing system has been continuously improved by the introduction of electrically driven hydraulic pumps, cage and column presses and, more recently, open mono-block super-presses that permit reaching pressures of 350-500 atmospheres. Other possibilities for mechanically extracting olive oil were implemented in the 1900s as a result of studies on percolation and centrifugation systems. These innovative systems materialized in 1951 when Buendía built the Alfin percolation system prototype, and in the 1960s with the introduction of the Centriolive plant by Alfa-Laval, the first industrial decanter for the continuous centrifugation of olive paste. Nowadays, there are three extraction systems in use – pressure, percolation and centrifugation, although centrifugation is by far the most common in olive mills all over the world. Today, however, the modern concept of the processing system includes all the steps from the harvesting of the olives to their crushing and the oil extraction. Thus, the scheme below shows the steps of olive oil production from the tree to the bottle.

Olive Harvesting

Olive picking is an important operation that affects virgin olive oil (VOO) quality since its sensory quality depends on the health and ripeness of the harvested olives. The olives, however, are no longer handpicked in most of the producer countries but are harvested by means of several kinds of shakers that transmit vibrations to all the tree branches. The olives drop onto a net that has been previously spread out under the tree canopy and then they are collected with vacuum systems.

The effectiveness of this mechanical picking is inversely proportional to the force of detachment of the olives, which diminishes as the olives ripen. Hence the more mature the olives are, the greater the percentage of olives dropped by the shakers. However, the olive ripeness is also a determinant variable in VOO quality, and olive oil from overripe olives is characterized by ripe flavor and a sweet taste that is often less appreciated by consumers than oils characterized by a slightly bitter taste and green aroma. Thus, the harvesting time is a compromise between olive oil quality and harvesting efficiency, which is partially solved with a simple visual inspection of the olives by the foreman. The degree of ripeness of the olives can be determined by using the next table that classifies olive ripeness into 7 levels according to their corresponding visual characteristics. Levels 5 and 6 are commonly preferred by producers to obtain extra-virgin olive oils.

| Level | Olive visual characteristics | |

|---|---|---|

| 0 | Bright-green skin | |

| 1 | Green-yellowish skin | |

| 2 | Green skin with reddish spots | |

| 3 | Reddish-brown skin | |

| 4 | Black skin with white flesh | |

| 5 | Black skin with <50% purple flesh | |

| 6 | Black skin with ≥50% & <100% purple flesh | |

| 7 | Black skin and purple flesh |

Transport of Olives to the Mill

Once the olives have been picked, the next step is their transport to the olive mill that may be at the farm itself or at a distance of several kilometers. In any case, the picked olives should be transported in such a way that air circulation prevents the rise of temperature on the bottom layers of olives, e.g. cases with a capacity of 2 5kg to 300 kg. Regardless of the transport system, the olives should be stored under optimal conditions from the moment of harvesting up to their processing at the mill. The time between both events should be no longer than two days to avoid significant changes in the oil sensory profile of healthy and optimally ripe olives. This step is the starting point of the diverse olive mill processes needed to produce virgin olive oil. The next figure describes each of the steps with the machinery used.

The olives arriving at the olive mill do not have the same characteristics: there will be olives of various cultivars, at different levels of maturity and even in different sanitary conditions (e.g. infested by parasites), which demands the classification of batches according to pre-established quality levels. Thus, batches are weighed and later inspected by an expert who channels them to the reception lanes that match their quality. A sample of olives representative of the whole batch is randomly taken for several analyses: humidity, free acidity, yield and sensory assessment.

Olive Batch Cleaning

The current harvesting process does not prevent the accidental collection of foreign materials with the olives. These materials could be harmful to the olive mill machinery and they could also modify the sensory attributes of the extracted olive oil, e.g. the presence of leaves increases VOO bitterness. Thus, the processes of removing foreign materials and washing the olives are necessary as soon as they reach the olive mill. The machinery consists of powerful fans, which remove foreign vegetable material, and pipes with forced water circulation in which olives are washed. The washing step avoids olive oil being qualified as having negative sensory attributes such as muddy sediment and earthy amongst others.

Olive Crushing

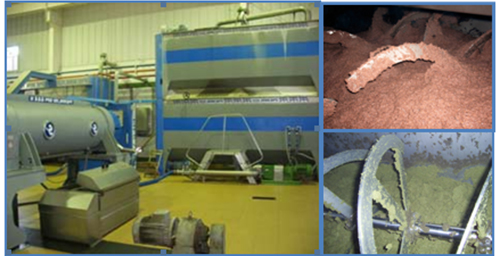

Cleaned and washed olives are then put on a moving belt to the processing zone of the olive mill. Modern olive mills, which are semi- or fully automated, have progressively substituted the old crushers made of granite by metal crushers. They consist of a metal body and a piece of various shapes that rotates at high speed. All the pieces are made of stainless steel. The piece that throws the olives against a fixed or a mobile metal grating, is most commonly hammer-shaped, but there are alternatives like toothed disks, cylinders, rollers, etc.

The thickness and texture of the crushed paste varies with the ripeness of the olives and hence the type and speed of the crushers should be adjusted by the technician to avoid overheating the olive paste, thereby helping to minimize any tendency to oxidation. A crusher with small holes in the grating, for example, gets a high extraction yield and the resulting oil contains high amounts of phenols, and hence it will be bitter. Thus, the crushing process is important in order to guarantee the taste and aroma of the end product and also the yield of the extraction process.

Olive Paste Malaxation

Metal crushers can cause emulsions that lower yield, but the mixing or malaxation operation diminishes this effect by causing the droplets produced by crushing the olives to coalesce, thereby increasing the percentage of available oil. Malaxation is a key step in the whole olive oil extraction process as good malaxation means optimal oil extraction and good values of antioxidants and flavor.

The malaxation involves stirring the olive paste slowly, which aids in the coalescence of small drops into large ones and favors the breakage of the unbroken cells containing oil. The malaxers have two or three cylindrical vats in tandem, each one with a rotating helix with several wings that mix the paste at low speed (15-20 rpm) for a period of time between 30 min and 75 min, depending on the paste characteristics. The vats are made of stainless steel and have double walls for circulation of heated water. Temperature and time are the variables of the malaxation process that are automatically controlled. The extraction yield is directly correlated to these variables; a rise in temperature and time increases the yield. However, the temperature of the paste should not be higher than 30°C to avoid change in the oil color (from yellow-green to reddish), the increase of acidity and the degradation of the volatile compounds that would result in a VOO with the negative sensory attribute “heated”.

The increasing interest for VOO with higher amounts of phenols has led to the modification of the malaxers, that now work in a nitrogen controlled atmosphere with around 2% oxygen content only, so producing VOOs of better sensory and nutritional quality if the temperature is inside the range of 25-27°C and the whole process lasts less than 60 min.

Liquid-Solid Separation

The main constituents of olive paste are liquids - olive oil and olive mill wastewater (OMW) - and solids such as small pieces of kernel and tissues. Next step is the separation of olive oil from the other constituents. Three different extraction processes can be applied to do this: pressure, percolation and centrifugation.

Modern olive oil mills extract VOO by means of centrifugation systems since they produce high-quality olive oils at lower production cost. The other processes, which are still in use in small olive mills and less-developed producer countries, are not described here but there is an interesting description in Di Giovacchino (2000).

Centrifugation is a continuous process that is able to separate olive oil from the other materials (water and solids) on the basis of Stoke’s law that determines the speed at which two nonmiscible liquids are separated under a centrifugal force. Separation is carried out inside a decanter, a cylindrical bowl with a co-rotating scroll with helical blades that rotate at 3500-3600 rpm. The small difference between the speed at which the bowl and the scroll rotate results in the movement of the solid (olive pomace) to one end of the decanter centrifuge, while oil and water (the other two constituents) are moved to the other end.

The paste is removed from the bottom of the malaxing vats by means of a mono pump that feeds the paste to the decanter centrifuge. Lukewarm water is added in order to increase the fluidity of the paste that is pumped into the three-phase centrifuge and help the separation of liquid and solid phases by the centrifugal force. The amount of water to be added is decided by the foreman, depending on the olive cultivar and the physical characteristics of the harvested olives, with best results varying from 1:0.6 to 1:1 paste/water (w/w).

The addition of water increases yield but also results in an increase of the amount of olive mill wastewater (OMW) (97.2 L/100 kg olives) that has negative environmental effects due to its resistance to biodegradation. Thus, a relatively new centrifugation process has been implemented in modern olive mills to avoid contamination. It is the so-called two-phase decanter that does not need the addition of water. Most of the world’s oil is produced with centrifugal decanters and the trend is towards the two-phase system. Circa 95% of Spanish olive mills, for example, operate with this kind of decanter.

The new decanters, which hardly consume water – only 5-10 L per 100 kg paste if olives are very dry - do not show significant differences compared with three-phase decanters regarding quality parameters, purity criteria and a general sensory assessment. The only exception is the bitterness perception due to a noticeably higher amount of phenols as consequence of the absence of water during the centrifugation process. The main disadvantage is the production of an olive pomace slurry (with 60-70% of water) that cannot be managed easily.

Liquid-Liquid Separation

Irrespective of the process used for oil extraction (pressure, percolation or centrifugation), a final centrifugation of the VOO is needed to remove water and small solids from the oil. This process is carried out in vertical centrifuges that rotate at high speed (6000-7000 rpm). Warm water is added to clean the oil of fine solids. The technician can adjust the ring size to adjust the phase separation point and hence the oil-to-water ratio at the exit.

Temperature and throughput are the other variables to be controlled. A low temperature can cause oil losses with the vegetable water, while an excessive temperature will produce an oil lacking in pleasant flavor. Oil will be insufficiently cleaned if not enough water is added. The objective of this step is to obtain cleaned oil with less than 0.2% of moisture and volatile matter (% w/w), and less than 0.1% of insoluble impurities in light petroleum (% w/w).

Virgin Olive Oil Storage

The whole process produces VOO, which is stored in large storage tanks that protect the oil from oxidation, and by-products. VOO should be stored in sealed stainless steel tanks, with nitrogen blanketing, and kept at about 15-18°C to avoid oxidation. Temperatures below 12°C would cause the oil to congeal due to the saturated fatty acids, while VOOs stored in outdoor tanks or exposed to oxygen, light and high temperature may be rancid in a few weeks.

Virgin Olive Oil Filtration

Although VOO does not have to be filtered prior to bottling, some consumers do not purchase bottles that show some sediment at the bottom despite the fact that filtered oils are less stable because some of the water-soluble components (mostly phenols) are removed. Diatomaceous earth is the commonly used filter aid.

Virgin Olive Oil Bottling

Glass is the ideal olive oil container as it is recyclable, impermeable to oxygen, allows airtight closure, does not transmit anything into the oil, and colored glass blocks light. The oil is usually bottled with nitrogen to extend the shelf life. Oils in clear glass exposed to light at room temperature, however, can lose the fruity/green aroma in two/three months and be rancid shortly thereafter.

By-Products of Olive Oil Production

The by-products are olive mill wastewater (OMW) and/or olive-pomace and, and less importantly, twigs and leaves. OMW is a dark red, acidic (pH 4.6-5.3) liquid of high conductivity with a high biological oxygen demand (20-55 g/L) that cannot be discharged into rivers. OMW consists of water (82-95% by weight), ash and mineral elements (N, Na, P, Ca, Fe, K), sugars, organic acids (e.g. acetic and glyceric acids), phenols, vitamins, fermentable proteins, waxy and resinous materials and other organic substances. The pollution impact of OMW, together with the potential economic interest of some of its constituents (mostly phenols), has increased the interest in olive mill wastewater management.

Olive pomace, either from three- or two-phase decanters, having a water content of 50 to 65%, contains olive oil (2.5-6%) that is extracted by solvent (usually hexane) after the pomace has been dried. Olive pomace from a two-phase decanter has to be heated to a high temperature, due to the moisture content, and it increases the cost and also the risk of generating polycyclic aromatic hydrocarbons (PAH). The de-oiled pomace can be used as agricultural fertilizer due to its high content of organic matter and mineral elements (N, P, K). Another alternative is the use of the pulp for animal feed and the stone fragments as fuel or in the manufacture of furfural or active carbon.

| Advantages and disadvantages of the olive mill process. Chemical and sensory variables affected by the processes | ||||

| Process | Advantages | Disadvantages | ||

|---|---|---|---|---|

| Harvesting (by shakers) | Low-cost harvesting. Better harvesting for olives and trees. |

If the amount of olives delivered at the olive mill is higher than olive mill capacity, olives will have to be stored days before processing. | ||

| Washing | Cleans olives. Removes earth, mud, leaves, twigs etc. Protects machinery against mineral materials. Avoids undesirable sensory attributes. |

Loss of olive oil in case of overripe olives. Need for a water recycling system. |

||

| Crushing by metal crushers | Low cost. High hourly working load. There are several kinds of crushers at various speeds. |

Can produce emulsions. Increases the temperature of the paste by 6-10°C. Lower amount of volatiles than old granite crushers. |

||

| Mixing | Essential process. Automatic control of time and temperature. Can work with inert atmosphere (N2). |

Some olives need the addition of adjuvants (micronized mineral talc). | ||

| Pressure | Simple & reliable machinery. Low investment. Low energy consumption. No water consumption. Less wet pomace. Minimum OMW1 production. |

Need for strict hygienic working conditions. Lower scores in sensory assessment. High labor costs. Low working load. Discontinuous process. |

||

| Percolation | Operates at room temp. No water addition. The highest olive oil quality. Low investment. |

Semi-automated process. Low yield. Not applicable to all olives. Low working load. |

||

| Three-phase decanters | Low labor cost. Fully automated process. High yield and quality oils. Only 3-5% oil in olive pomace. |

High investment. Energy & water consumption. High volume of OMW. High investment in OMW treatment plants. |

||

| Two-phase decanters | Low labor cost. Low OMW effluents. Fully automated process. High yield and quality oils. High amount of phenols. |

High investment. High wet olive pomace. Low price by-products or high investment in hermetic machinery for drying the olive pomace. |

||

| 1 OMW, olive mill wastewater. | ||||

Bibliography and Further Reading

- Alba, J. Elaboración del aceite de olive virgin. pp. 657-698. In: El cultivo del olivo (D. Barranco, R. Fernández Escobar and L. Rallo (eds.), Mundi-Prensa, Madrid, Spain) (2008).

- Aparicio, R. and Harwood, J.L. (eds.). Manual del Aceite de Oliva (Mundi-Prensa, Madrid) (2003).

- Aparicio, R., Morales, M.T. and Alonso, M.V. Relationship between volatile compounds and sensory attributes of olive oils by the sensory wheel. J. Am. Oil Chem. Soc., 73, 1253-1264 (1996).

- Di Giovacchino, L. Technological Aspects. pp. 17-59. In: Handbook of Olive Oil: Analysis and Properties (J.L. Harwood and R. Aparicio (eds.), Aspen, Gaithersburg, MA) (2000).

- García-González, D.L. and Aparicio, R. Research in olive oil: Challenges for the near future. J. Agric. Food Chem., 58, 12569-12577 (2010) (DOI: 10.1021/jf102735n).

- García-González, D.L., Aparicio-Ruiz, R. and Aparicio, R. Olive Oil. pp. 33-72. In: Gourmet and Health-Promoting Oils (R.A. Moreau and A. Kamal-Eldin (eds.) AOCS Press, Urbana, IL) (2009).

- Kapellakis, I.E.,Tsagarakis, K.P. and Crowther, J.C. Olive oil history, production and by-product management. Rev. Environ. Sci. Biotechnol., 7, 1-26 (2008) (DOI: 10.1007/s11157-007-9120-9).

- Morales, M.T., Luna, G. and Aparicio, R. Comparative study of virgin olive oil sensory defects. Food Chem., 91, 293-301 (2005) (DOI: 10.1016/j.foodchem.2004.06.011).

In This Section

- Marine Oils

- Animal Fats

- Olive Oil

- Palm Oil

- Seed Preparation

- Expanding and Expelling

- Solvent Extraction

- Meal Desolventizing, Toasting, Drying and Cooling

- Introduction to Degumming

- Chemical Degumming

- Enzymatic Degumming

- Alkali Refining

- Optimization of Bleaching Process

- Silica Hydrogel and its Use in Edible Oil Processing

- Deodorization

- Hydrogenation Mechanism

- Chemical Interesterification

- Enzymatic Interesterification

- Solvent Fractionation

- Dry Fractionation

- Hydrogenation in Practice