Meal Desolventizing, Toasting, Drying and Cooling

The Author: Timothy G. Kemper, Desmet Ballestra North America, Inc., 450 Franklin Rd Ste 170, Marietta, Georgia (30067-7737), USA

1. Introduction

After the solvent extraction process, the de-oiled oilseed material may be in the shape of flakes, cake particles or expanded pellet particles soaked with solvent. The de-oiled oilseed material typically contains 55 to 70 weight % dry solids, 25 to 35 weight % residual solvent, 5 to 10 weight % moisture and less than 1 weight % residual oil [1]. The de-oiled oilseed material is normally at atmospheric pressure and 55 to 60°C in temperature. In many cases the de-oiled oilseed material contains anti-nutritional factors that can inhibit digestion. As is, the de-oiled oilseed material has no commercial value, is unsafe to transport, and requires further processing.

There are two potential processing paths for the de-oiled oilseed material coming from the solvent extraction process. Over 95% of the de-oiled oilseed material is processed by the desolventizing, toasting, drying and cooling process path to produce protein-rich meal for animal feed ingredient applications. Less than 5% of the de-oiled oilseed material is processed by the flash desolventizing and cooling process path to produce protein concentrates, protein isolates and soy flour for human and specialty animal feed applications.

In the meal desolventizing, toasting, drying and cooling process path the solvent is removed from the de-oiled oilseed material and recovered for re-use, the de-oiled oilseed material is toasted to reduce anti-nutritional factors, the de-oiled oilseed material is dried to within trading limit moisture requirements, and the de-oiled oilseed material is cooled to near ambient temperature to remain flowable during storage and transport. The resultant desolventized, toasted, dried and cooled product is commonly referred to as oilseed meal.

In the flash desolventizing and cooling process path the solvent is removed very quickly from the de-oiled oilseed material and recovered for re-use without moisture addition to protect the integrity of the proteins. The de-oiled oilseed material is then cooled to near ambient temperature. The resultant flash desolventized and cooled product is commonly referred to as flash desolventized material or white flakes.

2. Desolventizing, Toasting, Drying and Cooling Apparatus

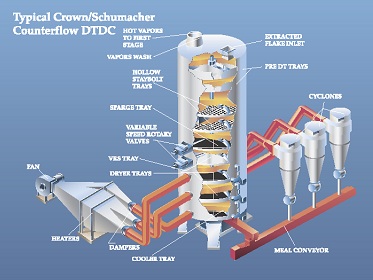

The desolventizing, toasting, drying and cooling processes can be accomplished in a single vessel referred to as a DTDC (Fig. 1). More commonly, the desolventizing and toasting processes are combined in one vessel, referred to as a DT, and the drying and cooling processes are combined in a separate vessel referred to as a DC.

Figure 1. DTDC iIllustration courtesy of Crown Iron Works).

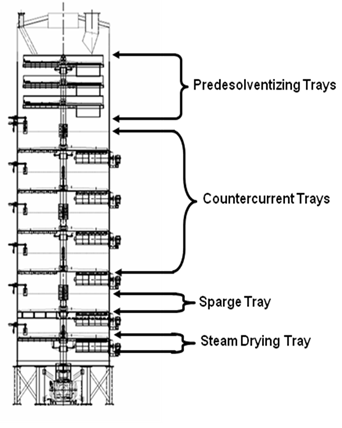

DTs are vertical, cylindrical vessels with a multitude of horizontal trays. The extracted material enters at the top and is supported by the tray. The material is mixed above each tray, and conveyed downward from tray to tray, by agitating sweeps anchored to a central rotating shaft. The heat for increasing meal temperature and evaporating the solvent is supplied by steam, introduced directly and indirectly into the meal via the trays. The trays of the DT are designed with an upper plate, lower plate, and structural members between designed to hold pressurized steam. The DT has four different types of trays; pre-desolventizing trays, countercurrent trays, a sparge tray, and a steam drying tray (Fig. 2).

Figure 2. DT tray configuration.

The DT pre-desolventizing trays have the sole purpose of providing conductive heat transfer through their upper surface to the solvent-laden material supported above. The steam is typically held at 10 barg pressure within the pre-desolventizing trays, providing a surface temperature of 185°C. Steam condenses within the tray, providing its latent heat to maintain the 185°C tray surface temperature and allow heat to be conducted into the solvent-laden meal layer above. A DT may have as many as seven pre-desolventizing trays, or as few as one. The number of pre-desolventizing trays is selected after doing a mass and heat balance to reach a target meal moisture at the exit of the DT. The pre-desolventizing trays are located in the upper portion of the DT and must allow ascending vapors from below to pass around them to the vapor exit at the top of the DT. Most manufacturers design disc-shaped trays providing space for the ascending vapors to pass between the outside perimeter of the tray and shell wall, while others design doughnut-shaped trays providing space for ascending vapors to pass between the inside perimeter of the tray and the central shaft. As an alternative to a large number of pre-desolventizing trays, the upper section of the DT is often expanded in diameter to enable fewer, larger diameter trays.

The DT countercurrent trays have three purposes: providing conductive heat transfer through their upper surface to heat wet material supported above, providing convective heat transfer through their lower surface to superheat direct steam swirling below, and providing apertures for direct steam to evenly ascend up through the tray and into the meal supported above. The steam is typically held at 10 barg pressure within the countercurrent trays, providing a surface temperature of 185°C. Steam condenses within the tray, providing its latent heat to maintain the 185°C tray surface temperature and allow heat to be conducted into the meal layer above, and transferred into the direct steam swirling below. A DT will have from one to four countercurrent trays. The number of countercurrent trays is selected to achieve a target residence time of the meal contacting stripping steam, typically 25 to 30 minutes for soybean meal and 60 to 90 minutes for rapeseed meal. The countercurrent trays are located directly under the pre-desolventizing trays in the center of the DT. The apertures in the trays must allow the direct steam swirling below to pass through the tray and into the meal supported above. There are three designs of countercurrent trays with differing apertures for allowing the ascending direct steam to pass through. Greater open area in the countercurrent trays allows for more uniform steam distribution and has been the trend in modern DT design. The original countercurrent tray design used hollows stay-bolts as apertures and generally had 1 to 2% open area for the vapors to ascend upward [4]. A later design used hollow stay-pipes capped by a perforated plate, with generally 2 to 4% open area for vapors to ascend upward. The latest design uses hollow stay-pipes capped with stainless steel slotted screens, with generally 7 to 10% open area for the vapors to ascend upward [3].

The DT sparge tray has the dual purpose of providing a uniform means of introducing direct steam into the meal layer, and providing conductive heat transfer through its upper surface to the wet material supported above. The direct steam introduced through the sparge tray provides approximately 75% of the total heat required for desolventizing and heating the meal in the DT. The sparge tray is typically designed with a plurality of apertures across its entire upper surface to evenly introduce direct steam into the meal. The size and quantity of apertures is calculated based upon the anticipated direct steam flow rate to provide a pressure drop of 0.35 to 0.70 bar. The direct steam supply is 10 barg pressure saturated steam (185°C) and after passing through a flow control valve, its quality changes to 0.35-0.70 barg pressure superheated steam (150-160°C). Therefore, the upper surface of the sparge tray is maintained at approximately 155°C.

The DT steam drying trays are designed with an upper plate, lower plate, and structural members between designed to hold pressurized steam. The steam drying trays have the purpose of providing conductive heat transfer through their upper surface to wet meal supported above. The steam is typically held at 10 barg pressure within the steam drying trays, providing a surface temperature of 185°C. Steam condenses within the tray, providing its latent heat to maintain the 185°C tray surface temperature and to allow heat to be conducted into the wet meal layer above. A DT may have as many as five steam drying trays, or as few as none.

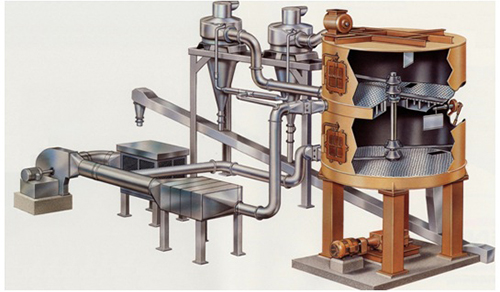

DCs are vertical, cylindrical vessels with a multitude of horizontal trays (Fig. 3). The desolventized and toasted meal enters at the top and is supported by the tray. The meal is mixed above each tray, and conveyed downward from tray to tray, by agitating sweeps anchored to a central rotating shaft. The trays of the DC are designed with an upper plate, lower plate, and structural members between designed to distribute low pressure air vertically into the meal layer supported above. The DC has two different types of trays; air drying trays and air cooling trays.

Figure 3. DC (courtesy of Desmet Ballestra).

The DC air drying trays are designed with an upper plate, lower plate, and structural members between designed to hold low pressure air. The air drying trays are designed with a plurality of apertures across their entire upper surface to evenly introduce hot air into the meal. The size and quantity of apertures is calculated based upon the design air flow rate to provide a pressure drop of 0.02 to 0.03 bar. These apertures are generally small round holes, with some DCs also using narrow slots. The DC many have from 1 to 6 air dryer trays. The number of air drying trays is determined to allow adequate hot air to pass through the meal to remove moisture to the target value.

3. Desolventizing, Toasting, Drying and Cooling Process

De-oiled oilseed material enters the DT at a temperature of 60°C, and contains 25 to 35% by weight of solvent. The solvent-laden material is stirred across the surface of the pre-desolventizing trays by the rotating sweeps. Since the heat is transferred into the meal layer by conduction, a shallow layer of 150 to 300 mm meal depth is held above each tray. The solvent-laden meal temperature is increased to approximately 68°C and approximately 10 to 25% of the solvent is evaporated on the pre-desolventizing trays.

The material exits the pre-desolventizing trays of the DT and falls onto the top countercurrent tray. This is perhaps the most critical tray of the DT. Since most of the heat is transferred into the meal layer by condensation of direct steam, a deep layer of 1000 to 1200 mm meal depth is held above the tray. The solvent-laden meal is stirred above the top countercurrent tray by the rotating sweeps. The direct steam passes from below up through apertures in the countercurrent tray. As the direct steam penetrates the upper meal layer, it reaches the solvent-laden meal and condenses, providing direct latent heat to evaporate solvent. The solvent evaporates and exits the meal layer as vapor. The condensation of steam causes the meal exiting the tray to be wet, typically in the range of 17 to 22% moisture. After the majority of the solvent evaporates, the meal temperature increases by direct and indirect steam heat, surpassing 100°C before the material exits the tray. The protein solubility of soybean meal is reduced from approximately 90 PDI down to 45 PDI as a result of the elevated moisture and temperature conditions.

After the wet meal exits the top DT countercurrent tray, it has had over 99% of its solvent removed. On the remaining countercurrent trays and the sparge tray, the meal is typically held in a 1000 mm deep layer on each tray to provide residence time for stripping solvent and toasting. The wet meal is stirred above each tray by rotating sweeps. The final desolventizing takes place as the ascending steam passing through the meal slowly strips out final traces of residual solvent down to 100 to 500 ppm. The meal temperature increases from 100°C up to 105 to 110°C, and the meal moisture decreases approximately 1% before the meal discharges from the sparge tray. The meal color darkens slightly and provides the meal with a toasted color. For soybeans, anti-nutritional factors such as trypsin inhibitors and urease are reduced on these trays by maintaining the meal moisture and temperature elevated for a period of time. The protein solubility drops approximately 1 PDI for every minute the meal spends in the remaining countercurrent trays, the sparge tray and the steam drying trays. Ideal feed for monogastric animals (poultry and swine) is high in protein solubility, and ideal feed for ruminant animals (cattle) is low in protein solubility (high in rumen bypass protein). Meal residence time on the remaining countercurrent trays and the sparge tray is dictated by the degree of solvent recovery required as well as by meal quality parameters.

After the meal exits the DT sparge steam tray, it is typically 105 to 110°C in temperature and 16 to 21% moisture. It passes through a rotary valve feeder to the steam dryer trays. On the steam drying trays, the meal is stirred above each tray by rotating sweeps and typically held in a 250 mm deep layer to allow thermal drying to take place. Approximately 0.5% moisture is removed in each steam dryer tray, and the meal temperature holds steady at 100°C. The water vapor evaporated from the meal in the DT steam drying trays can be pumped by an ejector and have its heat recovered within the solvent extraction plant.

After the meal exits the DT steam dryer trays, it is 100°C and typically contains 15 to 20% moisture. From there it is conveyed to the DC air dryer trays where hot air is injected up through the meal. The air supplied to each air dryer tray is first filtered to remove dust, and then pressurized using a spark-proof centrifugal blower. The air for the dryer trays is passed through a steam-heated coil between the blower and the entrance to the dryer trays. After the air enters the trays, it flows upward through the meal at a nominal velocity of 14 to 21 m/min, partially fluidizing the meal. The meal evaporatively cools and the released moisture is transferred to the ascending air. The warm, damp air exits the top of the meal layer and then exits the sidewall of the DC to a cyclone collector to remove dust prior to discharge to atmosphere. The major source of heat for evaporating the moisture in the meal is the high temperature of the meal exiting the DT or the DC steam drying trays. When the meal drops in temperature from 100 to 38°C, the heat provided is adequate to reduce the meal moisture by 6.5%. For soybean meal, the trading rule moisture limit is 12.5%, therefore, if the incoming moisture from the DT steam drying trays does not exceed 19.0%, the DC will typically require no additional evaporative heat source to dry the meal. If additional heat is required for evaporating moisture from the meal, the air entering the meal dryer trays can be heated to temperatures up to 150°C prior to entering the air drying trays. The heat source can be recovered flash steam, hot glycol-water solution (oil cooler), or fresh steam. The air must have adequate capacity to carry out the moisture released from the meal without becoming saturated. Cold air can hold less moisture than warm air, so winter conditions may limit the moisture-carrying capacity of the air. If additional heat is required for increasing the dew point of the incoming air, the air entering the air dryer trays can be heated to temperatures up to 150°C.

After the meal exits the DC air dryer trays, it is typically 60°C and contains 12 to 13% moisture. From there it is conveyed to the DC air cooler trays where cool air is injected up through the meal. The air supplied to each air cooler tray is pressurized using a spark-proof centrifugal blower. After the cool air enters the trays, it flows upward through the meal at a nominal velocity of 14 to 21 m/min, partially fluidizing the meal. The meal continues to cool evaporatively and also cools convectively. The cool, damp air exits the top of the meal layer and then exits the sidewall of the DC to a cyclone collector to remove dust prior to discharge to atmosphere. Ambient air is heated approximately 5°C in temperature by the energy of the blower, before it blows into the air cooler trays of the DC. The meal cools down to within approximately 5°C of the air temperature passing through the meal. Therefore, the temperature of the meal exiting the DC is typically cooled down to within 10°C of ambient air. A suction blower fitted downstream of the DC can thereby reduce exit meal temperatures by up to 5°C by avoiding the heating energy of the upstream blower.

The dry cool meal is conveyed from the DC to outside the solvent extraction plant for size reduction and then on to meal storage. It is important to properly dry and cool the meal to prevent continued evaporative cooling in storage or transport, which will cause reduced flowability, solidification and bridging of the meal inside storage and transport vessels.

4. Desolventizing, Toasting, Drying and Cooling Summary

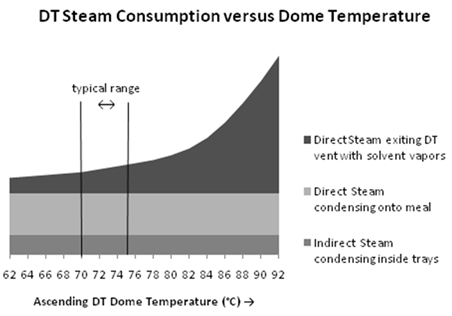

The steam consumed by the DTDC accounts for 75% of total extraction plant steam consumption [2]. An important parameter in the energy efficiency of the DT is the exit vapor temperature, also known as DT dome temperature. The steam that enters the DT is partially condensed in the trays, partially condensed onto the meal, and the remainder exits with the solvent vapor out the vent of the DT. The condensing sparge steam provides a plentiful supply of surface moisture on the meal, allowing the solvent and water to evaporate together as an azeotropic mixture. A mixture of 94% solvent with 6% water can vaporize as low as 62°C. Therefore, the lowest possible DT dome temperature would be 62°C. In practice, to maintain low solvent loss and maintain a safety margin, most modern DTs are operated with dome temperatures ranging from 70 to 75°C. As the DT dome temperature increases, the ratio of water vapor to solvent vapor increases in the vapors exiting the DT, and therefore total DT steam consumption increases as more sparge steam exits with the through the DT vent (Fig. 4). Therefore, to minimize total DT energy, it is very important to maintain a DT dome vapor temperature as low as safely possible.

Figure 4. DT steam consumption chart.

Determining the optimum DT and DC configuration for a given process application is rather complex. It requires determining all input parameters and calculating the mass and heat balance of both the DT and the follow-on DC. The mass and heat balance of the DC will determine the maximum allowable DT exit moisture, which will minimize meal drying energy. This moisture is generally in the range of 18 to 19%. With the DT exit moisture determined, the amount of direct steam introduced into the meal can be calculated. The DT diameter is generally determined by the direct steam flow rate per unit area. It is important to have a sufficiently high direct steam flow rate per unit area for adequate solvent stripping. The number of countercurrent trays is determined by the residence time needed to balance meal quality with residual solvent objectives. By calculating the total DT heat demand and subtracting the heat supplied by live steam, the total heat supplied by indirect steam can be determined. The total heat supplied by indirect steam less the heat supplied by countercurrent tray indirect steam will provide the amount of indirect steam heat needed to be supplied by the pre-desolventizing trays. With this data in hand, the diameter and quantity of pre-desolventizing trays can be selected. Major manufacturers of DTs utilize process simulation tools to assist processors in optimizing the DT configuration for a given application.

5. Flash Desolventizing and Cooling

The alternative process path for de-oiled oilseed material leaving the solvent extraction process is flash desolventizing and cooling [5]. In this process the de-oiled oilseed material is fed into a high-velocity stream of solvent vapors superheated to approximately 150°C. The de-oiled oilseed material enters the tube at approximately 55 to 60°C with 25 to 35% liquid solvent and 8 to 10% moisture. The superheated solvent vapors convey the material in a loop-shaped tube at approximately 20 m/sec velocity. Specific heat in the superheated solvent vapor stream is given up to provide the latent heat for the liquid solvent and some moisture in the material stream to evaporate. Approximately 2 seconds after entering the tube, the de-oiled oilseed material exits the tube at approximately 100 to 105°C with 1 to 2% liquid solvent and 6 to 8% moisture remaining. The superheated solvent stream drops in temperature to approximately 110°C after the material is discharged and then proceeds to a blower to restore the velocity and a heater to re-warm the superheated solvent vapors to 150°C before the tube approaches the material inlet point of the loop. Excess solvent and water vapors created in the tube exit an automated pressure control valve to a condenser.

The solvent level of 1 to 2% is too high to safely handle this flash desolventized material. Therefore, it is further conveyed into a flake stripper vessel and contacted with superheated steam to strip out the remaining solvent down to less than 2000 ppm remaining. In more recent installations, the flake stripper vessel is maintained under approximately 0.5 barg vacuum to help reduce residual solvent down to less than 500 ppm remaining. The flake stripper vessel may be a vertical tray type vessel, or horizontal conveyor type vessel, or horizontal paddle mixer type vessel. To maintain the PDI of the meal as high as possible, none of the superheated steam can condense. Therefore, it is critical that this flake stripper vessel is traced with hot water and very well insulated. For protein isolates and specialty flour applications the desired PDI is as high as possible (85 to 90 PDI). In these cases, heated surfaces in the flake stripper are maintained at 90 to 100°C. For protein concentrate applications, the desired PDI is commonly around 70 PDI. In this case moisture is sprayed into the flake stripper and/or the heated surfaces are operated at higher temperature.

The temperature of the flash desolventized material exiting the flake stripper is typically 90 to 100°C. This temperature is reduced to within 10 to 20°C of ambient by passing air through the material. In small-capacity plants, this cooling is accomplished in a dilute phase pneumatic transport system, while in large-capacity plants, this cooling is accomplished in a DC (as described earlier). The cool product is commonly referred to as white flakes. For white flakes going into specialty soy flour applications, the air used in the cooling process must be filtered through a biological filter to remove any bacteria. For white flakes going into a protein concentrates or protein isolates process, this is not critical as any bacteria will be eliminated downstream.

For protein concentrates applications the integrity of the flake shape is important and fine material needs to be screened away. For specialty flour applications and protein isolates applications, maintaining the shape of the flash desolventized material is not important, as size reduction is a normal process step downstream.

References

- Anderson, D. A primer on oils processing technology. In: Bailey's Industrial Oils & Fats, Sixth Edition, Volume 5, Edible Oil and Fat Products: Processing Technologies, pp. 1-56 (F. Shahidi (ed.), John Wiley & Sons, Hoboken, NJ) (2005).

- Fils, J.-M. The production of oils. In: Edible Oil Processing, pp. 47-78 (W. Hamm and R.J. Hamilton (eds.), Sheffield Academic Press, Sheffield) (2000).

- Kemper, T.G. and Farmer, R.D. (The French Oil Mill Machinery Company), Desolventizer, US Patent 5,992,050 (1999).

- Schumacher, H.O. Apparatus for the treatment of flaky or granular material with gases or vapors in a continuous countercurrent treatment, US Patent 4,503,627 (1985).

- Witte, N.H. Soybean meal processing and utilization. In: Practical Handbook of Soybean Processing and Utilization, pp.93-116 (D. R. Erickson (ed.), AOCS Press and United Soybean Board, Champaign IL and St. Louis MO) (1995).

In This Section

- Marine Oils

- Animal Fats

- Olive Oil

- Palm Oil

- Seed Preparation

- Expanding and Expelling

- Solvent Extraction

- Meal Desolventizing, Toasting, Drying and Cooling

- Introduction to Degumming

- Chemical Degumming

- Enzymatic Degumming

- Alkali Refining

- Optimization of Bleaching Process

- Silica Hydrogel and its Use in Edible Oil Processing

- Deodorization

- Hydrogenation Mechanism

- Chemical Interesterification

- Enzymatic Interesterification

- Solvent Fractionation

- Dry Fractionation

- Hydrogenation in Practice